Are you still searching for rotex solenoid valve but can't find the best Solenoid Valve Supplier who offers timely delivery?

Rotex Automation offers over 71000 catalogue solenoid valves and over 6100 specialized Solution. The Broad categorization of Solenoid Valve is as follow:

STANDARD ROTEX SOLENOID VALVE

APPLICATION SPECIFIC ROTEX

SOLENOID VALVE

Fill Up The Form To Get In Touch

What Are The Major Pitfalls In your Solenoid Valve Selection Journey?

GET A FREE ROTEX SOLENOID VALVE SELECTION GUIDE

7 Common Problems That Solenoid Valve Users Faces,

Resulting In Million Of Dollars Loss

Our Application Engineering research suggests that if compatible or Right Solenoid valve is not used for given application it may give out sub optimum performance, making customer product technically less competitive. Due to which we find quite a few of our customers losing as large as 5 million USD worth of feasible business.

Not able to meet customize solenoid valve requirement due to incompetent Solenoid valve Manufacturer

Most customer desist customization as their current suppliers asks them huge development cost or huge volume commitments or very high per piece cost forcing them to settle with sub optimum design developed with standard solenoid valve. This just not kills the opportunity earning as high as 3,000,000 USD profits which is almost 31% of their current profits

Many customers have to wait 4 weeks to 12 weeks to get the standard catalogue product while customize solenoid valve development takes as long as 1.5– 2 years losing a huge opportunity for business and saving possibilities. These values we have found to be going as high as 11,000,000 USD which directly hits the bottom line.

Many times, post-dispatch lead time of solenoid valve from its plant location till it reaches and commissions at your customer location goes beyond 6 months because of which many time solenoid warranties are not fully protecting you from any mal-function during your warranty period. We find customer may lose around 4.5% of their total purchase of the solenoid valvewhich comes around 45,000 USD per year considering 1M USD purchase.

SIL2 and SIL3 certifications based on IEC 61508 are becoming basic requirement for safety critical applications and in multi part assembly involving solenoid valves it becomes a challenge to meet needed Dangerous λ values. It is seen even 10% lower Dangerous λ values creates big impact in overall calculations. Due to very few SIL3 certified solenoid valve suppliers in the world, customer struggles with no better option and have found to be losing as high as 17M USD revenue opportunities.

Many times customers are stuck with single source of solenoid valve especially due to adopting a particular mounting and piping layout suiting to existing solenoid valve supplier. Due to huge cost of change dual sourcing or alternate sourcing of the solenoid valves becomes a challenge. Due to this Monopolistic environment, the customers end up paying premium for existing solenoid valve designs resulting them to lose possible savings up to 37% - 57% per valve

If not addressed at the right time, these concerns can lead to:

Don’t let this happen to you! Connect with our Experts

Get Expert’s AdviceDon’t worry! Rotex Automation Will Help You

Did You Know that 80% of the customers don’t use the correct solenoid valve in their application, which causes them to lose 5 million USD worth of feasible business

ROTEX CORPORATE VIDEO

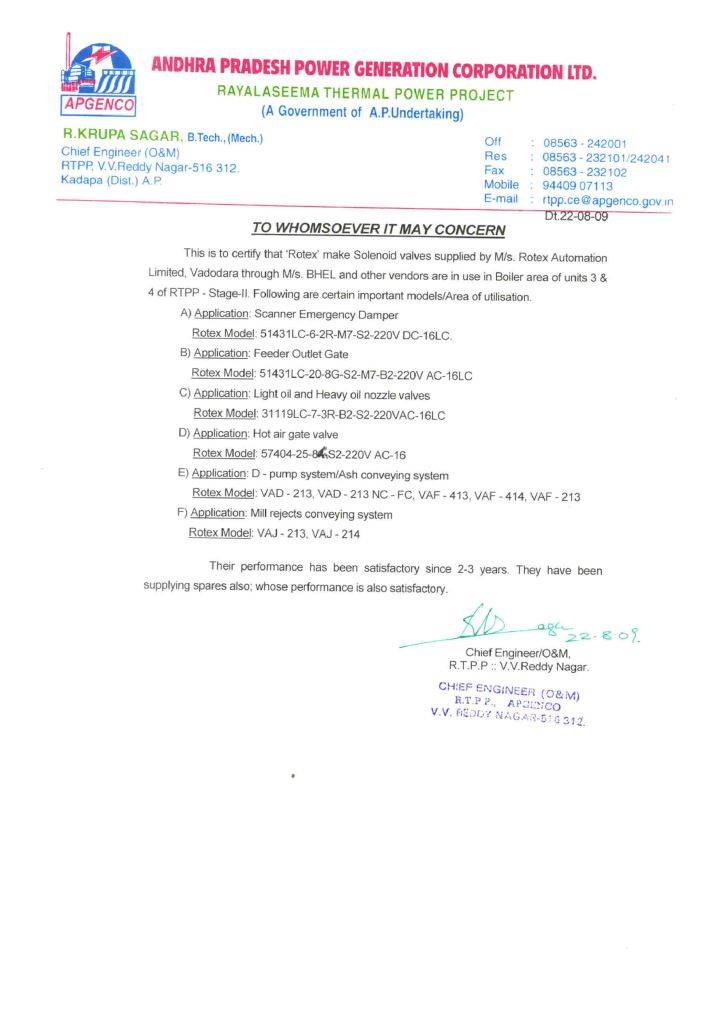

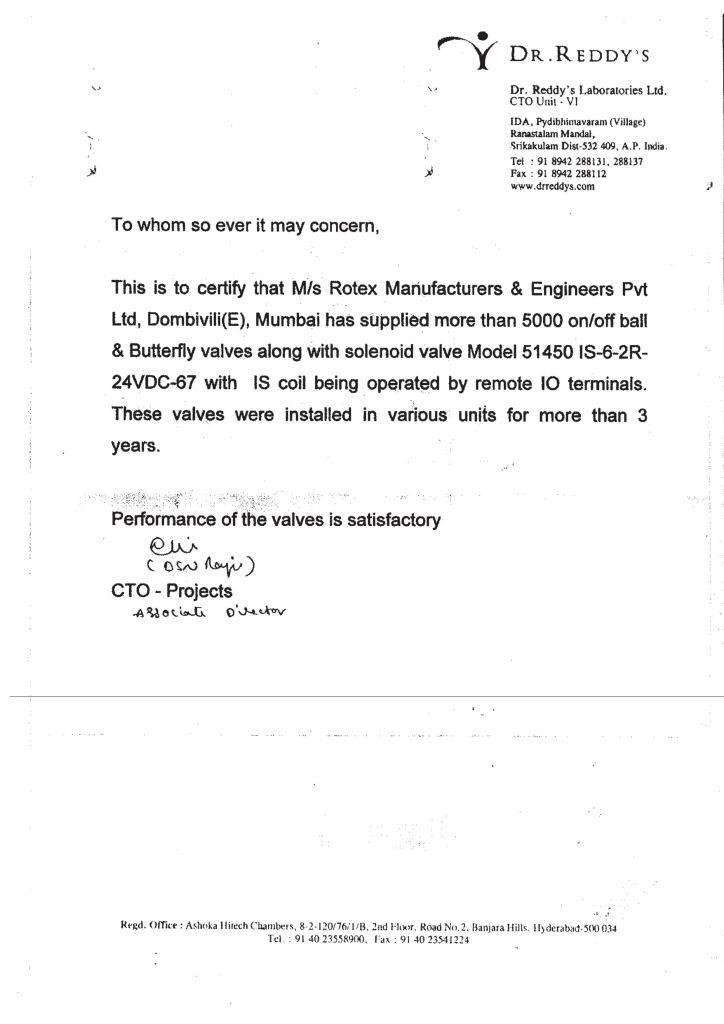

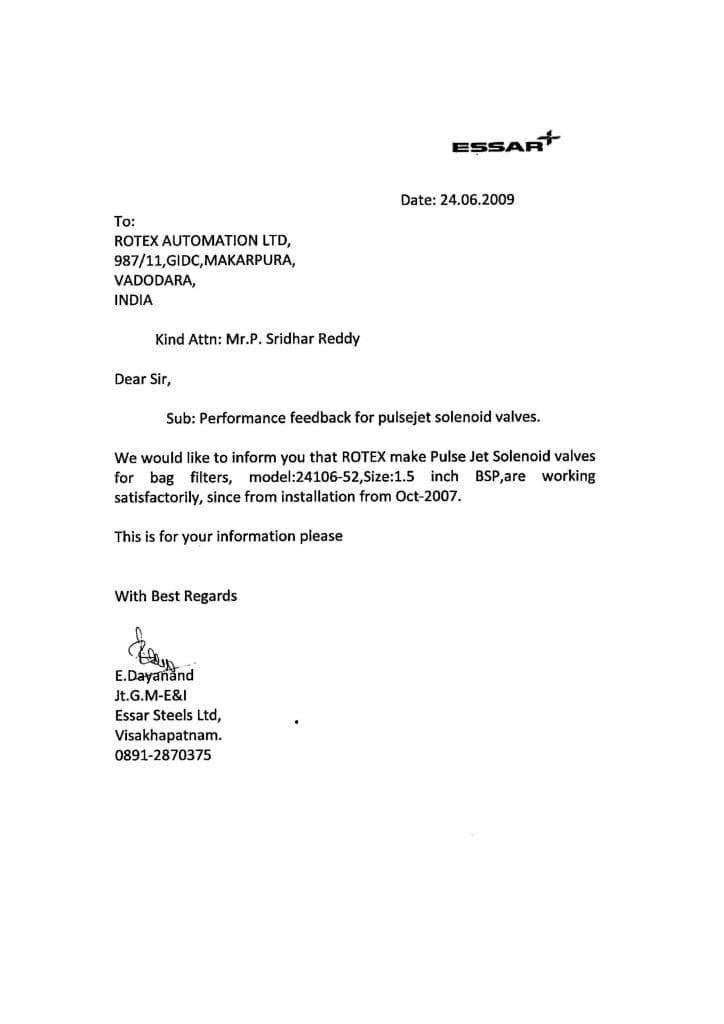

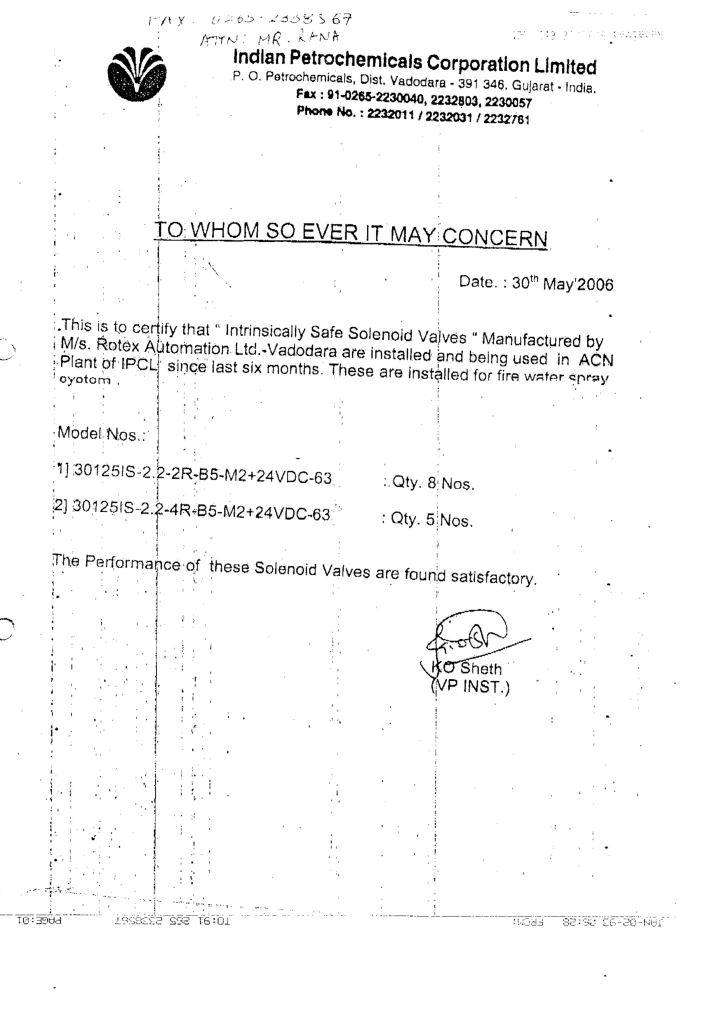

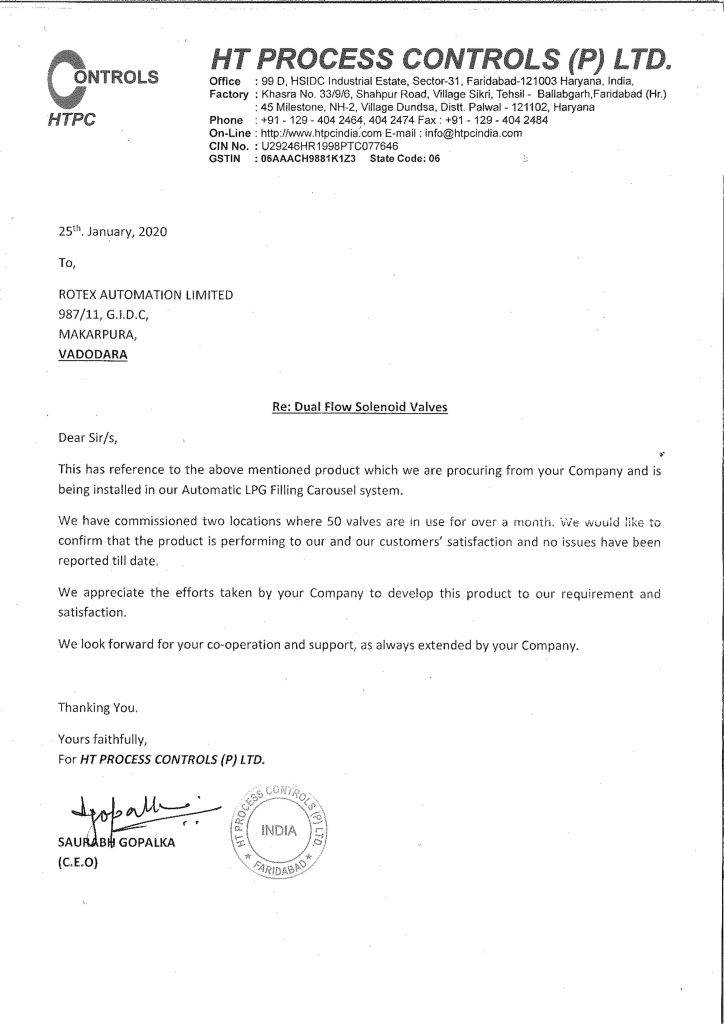

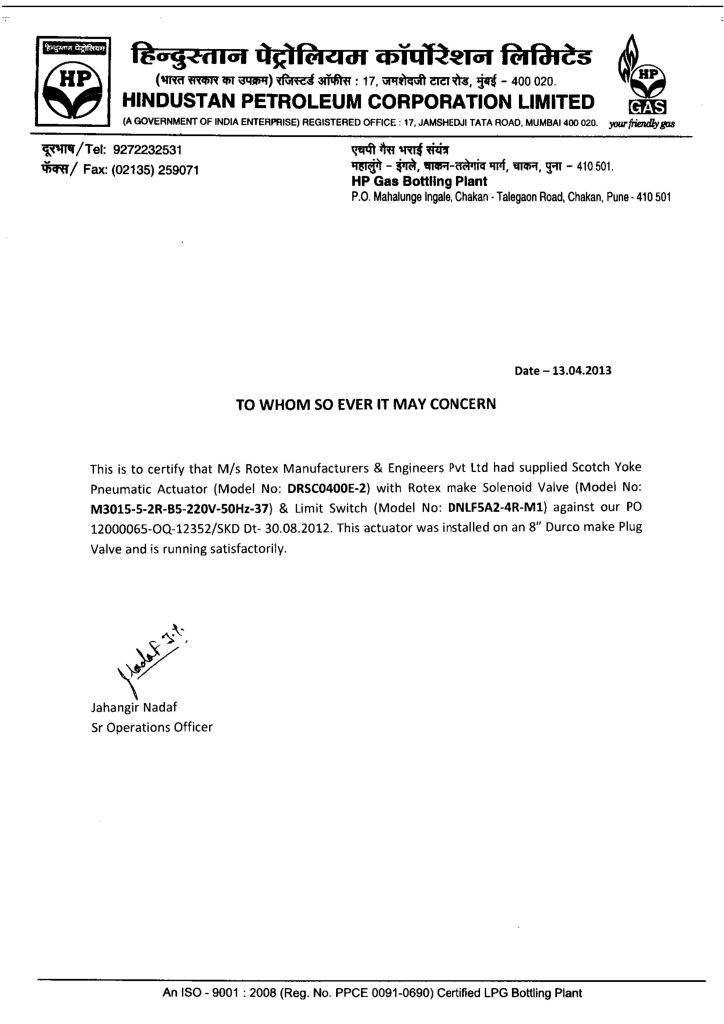

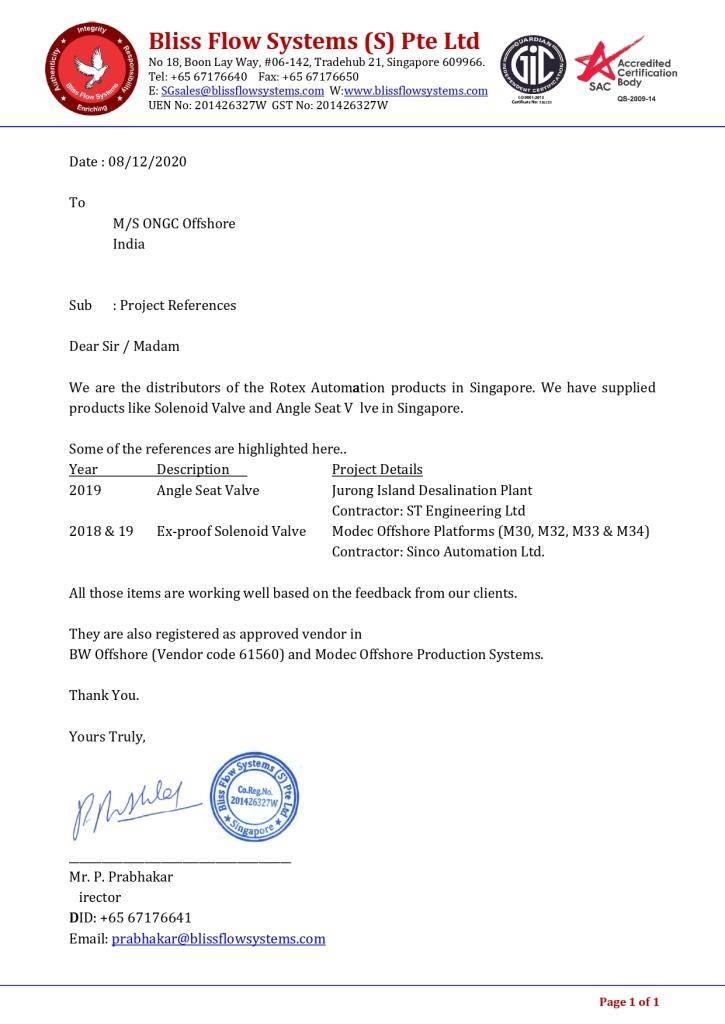

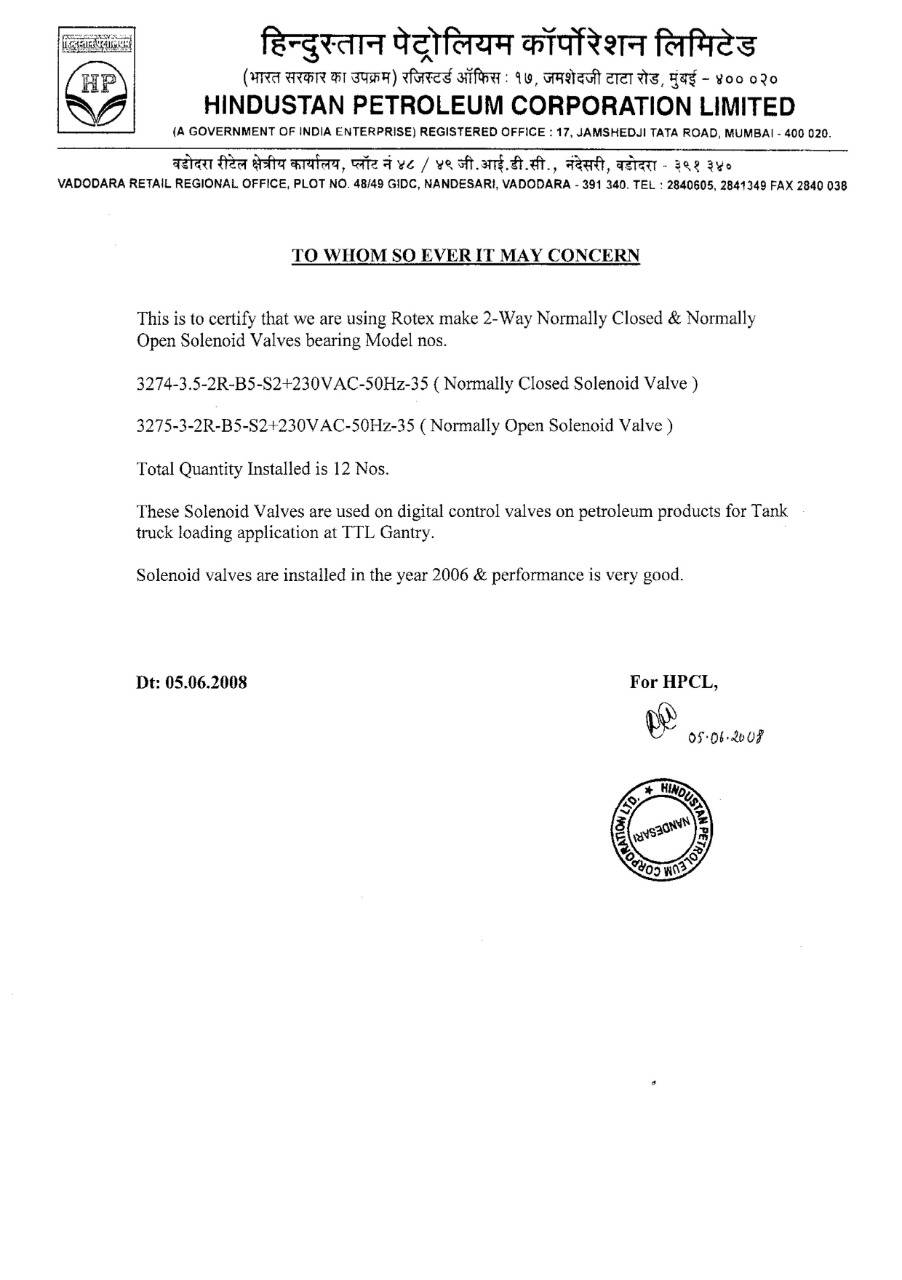

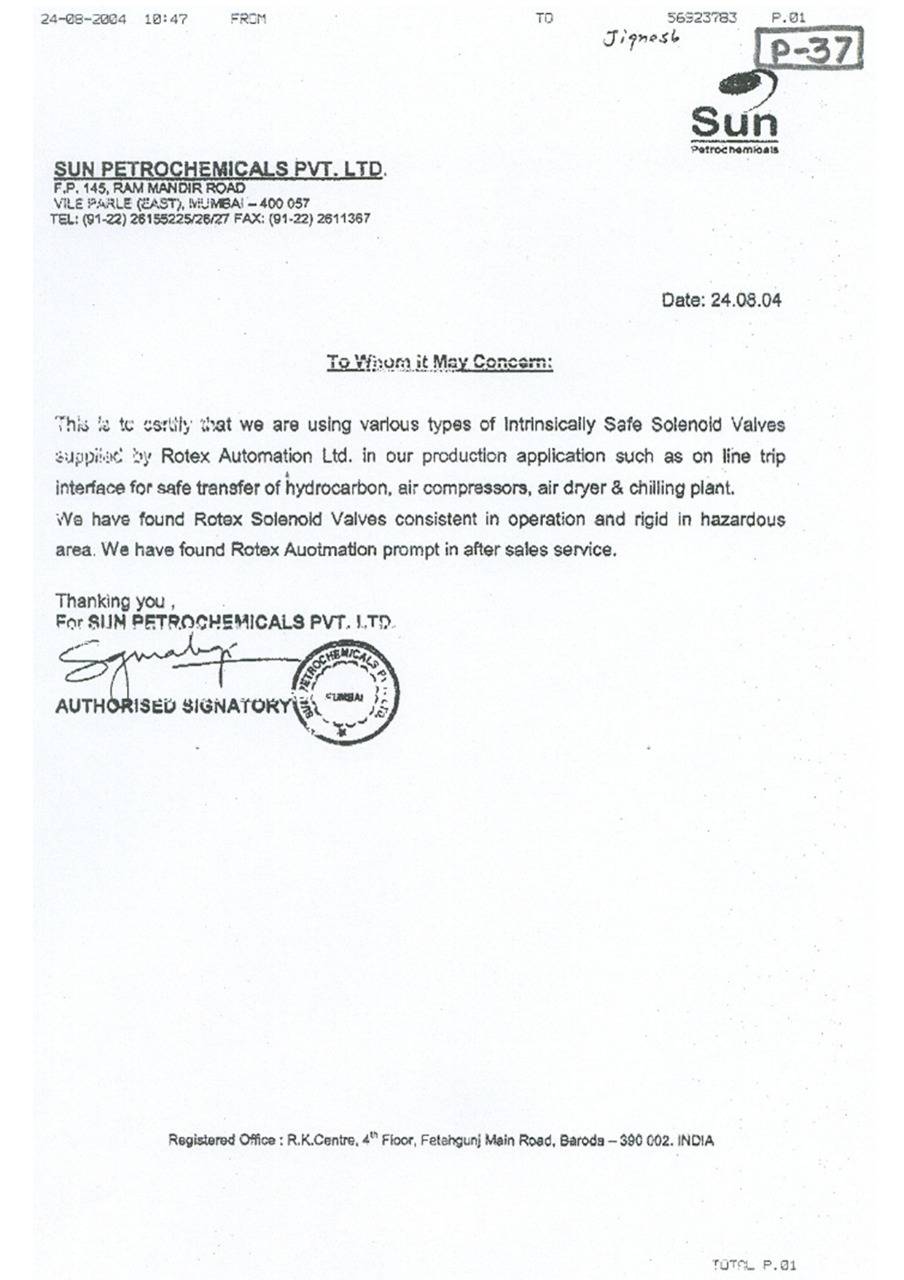

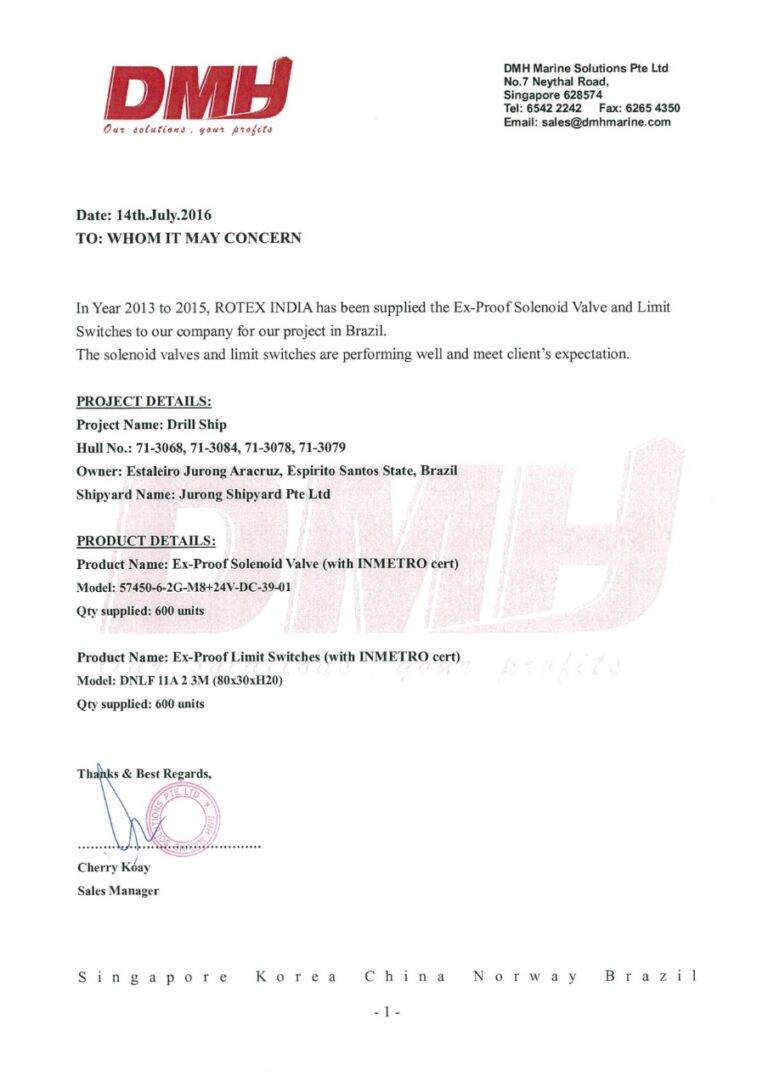

OUR CREDENTIALS

Let the Numbers Do The Talking

73+

Countries

9,000,000+

Installation

9,000+

Satisfied Customers

550

Days Warranty

800,000+

Annual Production

12

Utility Patents

11+

International Product Certification

43%

Export Revenue

Clients We Served

Industries We Serve

How Rotex as a solenoid valve manufacturer can help you save money or earn money

INSTANT BUYBACK OFFER: NOW REPLACE YOUR SOLENOID VALVE WITH A BRAND-NEW ROTEX SOLENOID VALVE.

537 customers have already replaced their valves. What are you waiting for?